Aircraft Transponder Inspection - Members Do more Learn more Save more - Earn more as a pilot - Click here

A reader recently asked me what the altitude/transponder check goal faced by aircraft owners every two years, given advances in avionics reliability.

Aircraft Transponder Inspection

Jeff Wall of Infinity Aviation performs altitude and transponder checks on SocialFlight's A36 Bonanza. Photo by Jeff Simon.

Eagle Creek Mros Complete 20 Phenom 10 Year Inspections

I thought this might be a great opportunity to answer a question while I await the biennial FAA-mandated pitot/static system, altimeter, and transponder inspection at Infinity Aviation in Nashua, New Hampshire.

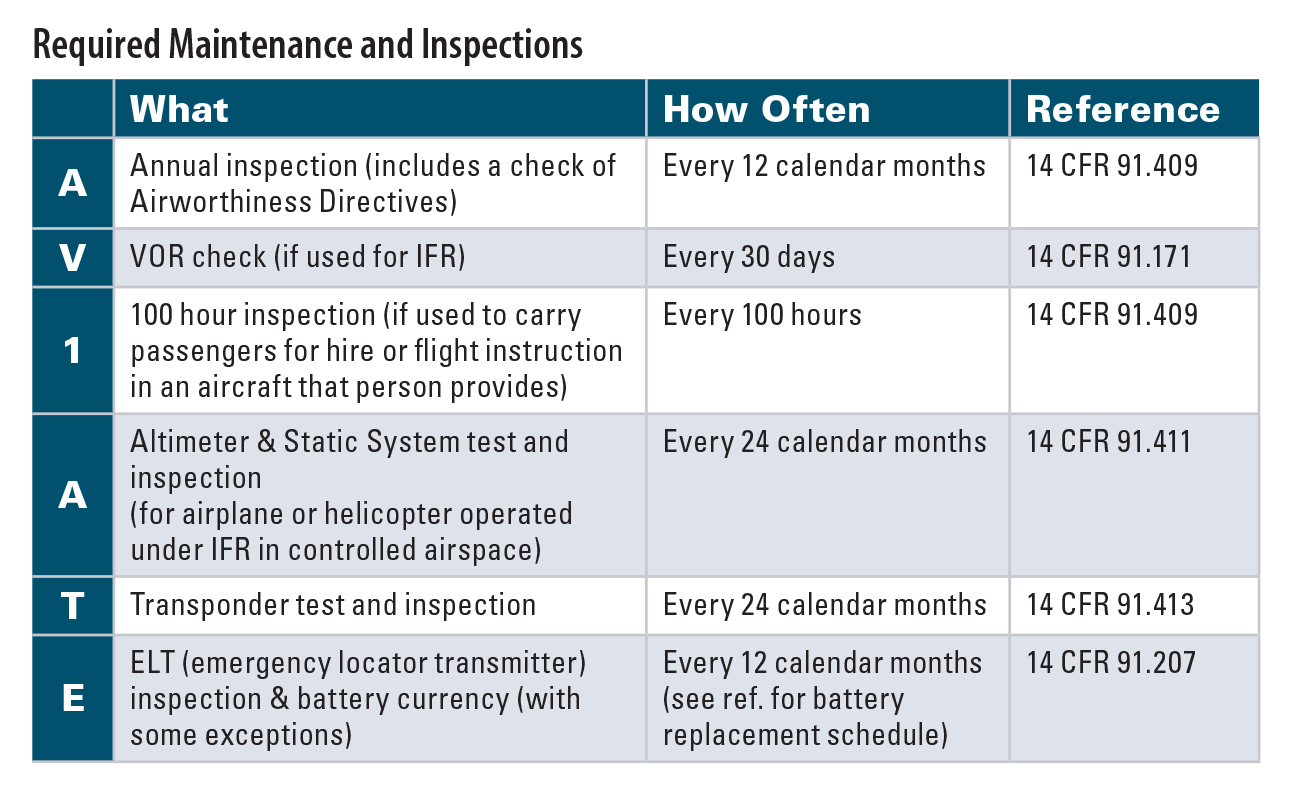

Altimeter (FAR 91.411): The aircraft's static, altimeter, and automatic altitude reporting system (Mode C) must be verified and tested within 24 calendar months prior to flight in IFR-controlled airspace. FAR 43 Appendix E, Altimeter System Testing and Inspection, lists the items that must be inspected.

Transponders (FAR 91.413): The transponder must be tested every 24 calendar months. FAR 43 Appendix F, ATC Transponder Inspections and Tests, lists the items that must be inspected. To use the transponder, it must be tested every 24 calendar months. In addition, the installation or replacement of the transponder should also be checked for data errors.

The need for this verification is obvious. After all, if you're flying in controlled airspace, air traffic controllers use the signal from your transponder, including the altitude encoder, to provide traffic separation between you and other aircraft. And if you're flying IFR, it's important to stay at the altitude indicated by your instruments. However, avionics and instrument technology has advanced dramatically since the time these regulations were originally written.

The Aircraft Electronics Association

Traditional analog altimeters are mechanical instruments that use a sealed hole to move a dial to indicate your elevation. Over the years, humidity, temperature, dust, corrosion, and many other factors affect the accuracy of the instrument. Therefore, the altitudes require regular testing and adjustment to ensure that the displayed altitude is within 25 feet of the altitude indicated by the calibrated test set. Similarly, older encoders also use a combination of mechanical and electrical designs to transmit aircraft altitude to the transponder (with similar failure modes and tuning requirements). Early transponders used analog "cloud tubes" which were prone to failure and calibration problems. This all adds up to a high probability that a biennial inspection of all these instruments would find enough problems to make a general aviation fleet-wide inspection requirement well justified.

But what now? With solid-state transponders and encoders becoming the norm and a growing fleet of glass panels without mechanical altimeters or airspeed indicators, does this routine check make sense? I had this same discussion with Jeff Wall at Infinity Aviation and was surprised to find that the answer was a resounding "yes."

"Everything that goes into this avionics is still mechanical," Wall said. "Pitot and static lines develop leaks, fittings become loose, and over time the elements affect the accuracy of solid-state devices as well." Even for planes that don't have mechanical altitudes, Wall still finds that about 50 percent of the planes he works on for his 24-month inspections need some form of leak repair or avionics tuning, even for panel-equipped planes. of glass.

In my case, our Bonanza is equipped with an Aspen EFD1000 Pro primary flight display, backup handheld altimeter, L3 Lynx ADS-B transponder, and Trans-Cal solid-state encoder. The Aspen, Lynx, and Trans-Cal passed with flying colors, but the altimeter needed to be adjusted to within the required 25-foot accuracy. Two years ago the same inspection found a large leak from a failed fitting in the static system. So while every other year I complain about having to take the plane to the avionics shop for its semi-annual inspection, the process seems like money well spent. Until next time, I hope you and your families stay safe and healthy and I wish you blue skies.

Aircraft Maintenance: Altimeter And Transponder Checks

Jeff Simon is an A&P mechanic, IA, pilot, and aircraft owner. He has spent the last 22 years helping owners maintain aircraft and has created the first transmission alternator coupling inspection tool available at ApproachAviation.com. Jeff is also the creator of SocialFlight, a free mobile app and website featuring over 20,000 aviation events, $100 burger destinations, and educational aviation videos. Free apps are available for iOS and Android devices, and users can also visit www.SocialFlight.com.

Aircraft Spruce provides just about everything a pilot or aircraft owner could need. As a strategic partner since 2012, the company sponsors programs that bring hands-on knowledge and a DIY spirit to members. If you have questions or would like to be added to the waiting list, click here to contact us.

Attendees will learn the proper methods of testing and inspecting pitot-statics and transponders. This full-day course provides an overview of the regulations and an explanation of the proper administrative procedures for completing these important certifications. Prepare and perform RVSM inspection tasks. An ADS-B session includes installation, cabling, and return to service.

I attended via live simulcast and it was like being in a classroom. The instructor was very knowledgeable and did a great job of keeping the course interesting. I learned a lot and I look forward to the next opportunity to attend the course. Additional thanks to Aaron Ward for going above and beyond to set up this learning website alive during the Covid pandemic.

Aircraft Vega 367x X Band Radar Transponder Navigational P/n 404856 1 Avionics

I learned a lot from this presentation and look forward to more opportunities to learn from you in the future. Thank you very much!

The tutorial is well worth the time and effort if you haven't done tests 91.411, 91.413 before.

The information they give you is worth the drive. Above what I expected from this class.

Spend the money and take this class, you won't be disappointed. This class is not beyond information and covers everything.

Gables G 3816 Aircraft Atc Transponder Control Panel

It's definitely worth the 8 hours because you're bound to learn something new no matter how long you've been involved in avionics.

Great for a guy just starting out in the dick/stat world, maybe not if he's been doing it for a long time.

The information is for you, pay attention and invest. Don't be afraid to ask questions.

The course covers a lot of information quickly, covering the basics and learning how to improve at your craft.

Aircraft Inspection: Guide To Keeping Your Plane Safe

Don Dominguez is so driven and passionate about what he teaches, time flies so fast.

Technicians will learn to plan, install, configure, and test a primary flight display, EHSI, and GPS/Nav/Com installation consisting of a dual Garmin GI 275, Garmin GTN 650 touchscreen, and Garmin GTX 345 transponder. Designed for technicians who have hands-on avionics installation experience and are seeking further training to integrate common general aviation installations.

This course is designed for technicians who have experience with basic avionics installation practices, are familiar with basic soldering skills, and are seeking experience in LRU bench testing and avionics troubleshooting. Bench tests of Nav, VHF Com and transponders will be the focus of the study. Technicians will create a general purpose test panel for use in the course. Attendees will keep their created quiz dashboard at the end of the course.

This course is designed for technicians with experience in basic avionics installation practices and seeking experience in LRU transponder bench testing, transponder flight line testing, and aircraft troubleshooting. ADS-B transponder systems will be the focus of study. At the end of the course, the participants will keep the wireframes they created.

Socal Jet Services

This course is intended for technicians who have experience in basic avionics installation practices and are seeking experience in avionics flight line testing, LRU bench testing, and aircraft troubleshooting. VOR, Localizer, Glideslope, Marker Beacon and VHF Comms will be the focus of the investigation.

This course is designed for the home builder or avionics technician who wants to learn how to perform an avionics installation on an experimental aircraft. The class focuses on the Garmin G3X Touch system and a simplified example harness is built as part of the hands-on portion of the class. Although the G3X Touch system is the main focus, the wiring principles and general guidelines can be applied to any experimental avionics system. From the DIYer to the avionics shop trying to carve out a niche, this class has something for everyone.

The company has developed a proprietary SMS program designed for technical organizations, small businesses, and used by a membership of 900 repair stations. This program is coordinated with the Federal Aviation Administration and Transport Canada Civil Aviation, as well as discussions with the Australian Government Civil Aviation Safety Authority and the European Union Aviation Safety Agency for future adoption. .

The Basic Avionics and Wiring Installation course is designed for certified repairmen, new avionics technicians, aviation maintenance technicians, and recent graduates interested in improving or acquiring the skills necessary to perform aviation installations. This three-day workshop uses detailed theory and hands-on lab exercises to immerse attendees in best practices used in planning, managing,

The Maintenance Maze

Aircraft transponder frequency, experimental aircraft transponder, aircraft transponder, aircraft transponder modes, aircraft transponder receiver, aircraft transponder check, aircraft transponder for sale, portable aircraft transponder, aircraft transponder tracker, aircraft transponder antenna, aircraft transponder codes, aircraft transponder test equipment

0 Comments